Back to:

Historical

Society

|

Notes from the Paynesville Historical Society. . . Wool used to make yarn

By Jennifer Gully

Before people were able to buy clothes on a regular basis, they had to make their own. It was common for women to make clothes out of yarn, which was made out of wool from sheep.

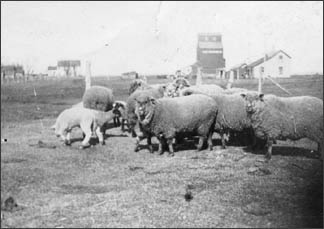

These sheep were raised on a North Town farm around 1916.

Starting with the right shoulder and neck, then to the top of the neck and left shoulder of the sheep. Next they would shear the sheepıs left side, belly, and center of the back. Shearing the sheep in one piece was finished with the inside of the back legs.

The best wool was on the sheepıs back, and the worst wool was on the sheepıs belly and legs. This was because the wool was very matted and dirty on the sheepıs underside.

Once the sheep was sheared the wool was cleaned. It was very normal for wool to be washed with mild homemade soap and soft rain water. The wool was then set on the grass to dry.

If the wool was not dirty it was preferred not to be washed. This is because wool has lanolin in it, which is an ingredient in lotion, so hands would be soft. Uncleaned wool with lanolin was easier to spin.

The next step was to card the wool. This was done with two wire brushes combing the wool back and forth. Carding the fleece was important because it removed the debris and disentangled the wool. The wool was made into little rolls with small cards and then it was ready to be spun into yarn.

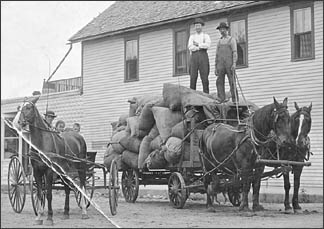

A load of locally-produced wool is ready for transportation in New Paynesville (the modern-day downtown) in 1913.

Until the 1300s, yarn was spun this way. In the 14th century, a high spinning wheel was used in Europe. This wheel has a much bigger diameter and was hand-powered. A low spinning wheel also known as a Saxon wheel was foot powered and yarn automatically went in the bobbin. Therefore yarn could be spun faster. This was invented 150 years after the first spinning wheel.

After the wool was spun into yarn it was put onto a niddy noddy, which measures the yarn into yards.

Once the wool was spun, many clothes were made. Clothes that were made included socks, scarves, hats, gloves, vests, and sweaters. Swimming suits were very common to be made out of wool, because it dries quickly.

At the museum there is a wool exhibit with sheep shears, cards, wool, spinning wheels, and hand-knitted clothes. In addition, there are wool swimming suits to view.

|

Sheep need to be sheared to get the wool off of them. Every spring sheep got sheared by cutting close to their skin and removing their fleece. It was best when the sheep fleece was cut off all in one piece.

Sheep need to be sheared to get the wool off of them. Every spring sheep got sheared by cutting close to their skin and removing their fleece. It was best when the sheep fleece was cut off all in one piece.  Spinning wool consists of twisting fibers together to make yarn or thread. There were different ways to do this. A drop spindle was the easiest to use because a person only needs to use their fingers. A drop spindle consisted of a round stick for the yarn to go on, and the whorl keeps the spindle going around.

Spinning wool consists of twisting fibers together to make yarn or thread. There were different ways to do this. A drop spindle was the easiest to use because a person only needs to use their fingers. A drop spindle consisted of a round stick for the yarn to go on, and the whorl keeps the spindle going around.