Master Mark expands in Paynesville

To meet the growing demand for its new composite decking, Master Mark Plastics is expanding its plant in Paynesville.

To meet the growing demand for its new composite decking, Master Mark Plastics is expanding its plant in Paynesville.Work started last week on the million-dollar project, which includes adding 21,000 square feet to the plant, erecting a 60-foot silo to house sawdust, and constructing a railroad spur from the plant to the Canadian Pacific rail line that goes through town.

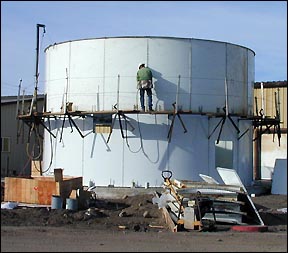

Workers have started erecting a 60-foot silo, which will hold sawdust for their composite decking - Rhino Deck - production lines.

The expansion is being driven by the success of Master Mark's newest product, Rhino Deck, a composite decking and rail system made of recycled plastic and sawdust. According to Randy Pflipsen, Master Mark's plant manager in Paynesville, the company started manufacturing the decking in January and hasn't been able to keep up with the demand.

The composite decking production lines in Paynesville have been running around the clock to try to meet demand, Pflipsen said.

Right now, the Paynesville plant has four manufacturing lines. Once more equipment arrives, five more lines will be added in late November or in early December.

Master Mark has switched the local plant entirely to the manufacture of Rhino Deck. Its lawn edging production has been moved to the Albany plant.

The Paynesville plant employs 75 people, but the expansion could eventually add 25 jobs, according to Pflipsen.

The company is anticipating that composite decking sales will top $25 million this year.

Master Mark primarily uses recycled plastic in its manufacturing process, but adds sawdust to the decking line. The company uses 280,000 pounds of sawdust per week.

Work started last Friday on a new silo, which will eliminate the need to handle bags of sawdust and make production easier. A conveyor will carry the sawdust from the silo to a blender at each production line.

On Monday, work started on a new railroad spur, which will connect the plant to the Canadian Pacific rail line that runs through town.

The rail access will help Master Mark save money on transportation costs. Each railroad car has three times the capacity of a semi-trailer, said Pflipsen, and company will save $3,000 on shipping costs to the west coast with each railroad car.

"The railroad spur will pay for itself quickly," said Pflipsen. It should take a week to 10 days to construct the spur line.

The Paynesville plant will also install a new microscreen in their wash system for recycled plastic early next year. This will cut the amount of water the plant uses per day from 30,000 gallons to 1,500 gallons.

There will be less water discharged into the sewer system, and it will also be cleaner. The microscreen will reduce the burden on the city's sewer system and it will lower Master Mark's water bills. Pflipsen expects the system to pay for itself within three years.

Besides making lawn edging and composite decking, Master Mark sells recycled plastic to other companies that use it to make drain tile.

The company recycles more than a billion plastic bottles each year, more than 50 million pounds, said Pflipsen. It recycles plastic from the five-state region (Minnesota, Iowa, Wisconsin, and the Dakotas) and beyond.

The city of Paynesville and Paynesville Township have approved a combined $278,000 in EDAP loans to Master Mark for the project. Total cost of the project is just over $1 million. Construction should be finished by next spring.

Contact the author at paypress@lkdllink.net • Return to News Menu

Home | Marketplace | Community