AMPI installs new cheese belt

Paynesville didn't make much cheese last week.

Paynesville didn't make much cheese last week. The Associated Milk Producers Inc. (AMPI) plant in Paynesville ceased production for four full days last week in order to install a new cheesemaking machine.

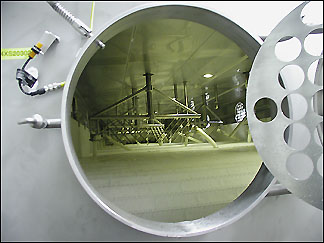

The new salting line being lifted into the plant.

The 90-foot, 32,000-pound, stirred-curd salting belt was installed at the Paynesville plant on Tuesday morning, Aug. 20, arriving in two 45-foot pieces. To get the new machine in the plant, a 15' by 15' hole had to be made in a wall on near the northeast corner of the plant.

The new salting belt (shown at right) is part of $2.5 million in upgrades at the plant, which will enable the plant to process an extra 500,000 pounds of milk per day into another roughly 50,000 pounds of cheese.

A growing milk volume by its members and a growing customer base prompted AMPI to do the expansion project, said AMPI general manager Mark Furth last week. "AMPI is continuing its long history of investing in the Minnesota dairy industry," he said. "This long-term investment improves our members' competitive edge in the marketplace."

Right now, the Paynesville plant can process around 1.6 million pounds of milk per day, producing around 165,000 pounds of cheese, according to Matt Quade, AMPI Paynesville Division Manager. The plant receives more than that in milk, and currently forwards raw milk to other AMPI plants for processing.

"This machine gives us the ability to process 2.1 million pounds of milk per day," said Quade.

The decision to invest in the Paynesville plant was made last winter by the AMPI corporate board, said Quade. AMPI ordered the automated salting table then, but had to wait until now for the custom-built machine to be delivered.

Workers have been at the plant on and off since the start of July to install the piping, the automated salt delivery system, the new system of catwalks, etc. for the new machine.

Last week, the plant did its normal production on Monday, ending around 12 midnight. Instead of the usual cleaning in preparation for the next day's production, though, workers immediately began removing the old salting tables, where plant workers added salt to the new cheese manually.

The plant was running at maximum capacity with those salting tables, said Steve Vaske, cheese plant supervisor in Paynesville. "It was just as tight as we could run them," he said. "A table would only hold so much cheese before it would run over the sides."

In addition to the new salting belt, the project costs included installation, electrical work, engineering, and a new vat that holds 60,000 pounds of milk, and reduces it through boiling to 45,000 pounds. This is the first step in turning milk into cheese.

In addition to the new salting belt, the project costs included installation, electrical work, engineering, and a new vat that holds 60,000 pounds of milk, and reduces it through boiling to 45,000 pounds. This is the first step in turning milk into cheese.

From there, the cheese curds go onto a 12-foot-wide belt in the new machine, which agitates the new cheese and slowly moves it through the 90-foot machine, at a rate of approximately one foot per minute. For the first 45 feet, the bacteria grows, and any whey that drips off is collected as sweet whey, which can be used in candy bars.

In the second 45 feet of the new machine, a series of 12 sprinklers add salt to the cheese, stopping the bacteria reaction. Whereas before, salt was manually added to giant tables of cheese curds, the new machine applies salt automatically and uniformly.

"This is the latest, state-of-the-art, the best technology for cheese making," said Quade. "Totally automated."

"We're going to have more consistent and better quality cheese," Quade predicted.

The new cheesemaking machine will also reduce the plant's required staffing by three positions per shift.

Increasing capacity should make AMPI more competitive in the cheese market, said Quade. "For the main part, my costs will remain the same with increased capacity, which will reduce the cost per pound for production," he said.

While the plant can now process more milk into cheese, it is not able to condense and dry the additional whey, a by-product of the cheesemaking process. The plant needs to be able to condense the whey before shipping it to a sister plant in Dawson to be dried and then sold.

While the plant can now process more milk into cheese, it is not able to condense and dry the additional whey, a by-product of the cheesemaking process. The plant needs to be able to condense the whey before shipping it to a sister plant in Dawson to be dried and then sold.

"We've addressed the cheese side to run more milk," said Quade. "Now we have to address the whey side."

The plant will continue at its present production run of 1.6 million pounds of milk daily until the AMPI board approves and increases the capacity for condensing whey. The AMPI board does have a track record of investing in the Paynesville plant, having spent $1.3 million on an automated block and barrel line in 1999. (The Paynesville plant produces 500-pound barrels and 640-pound blocks of cheddar cheese, most of which is further processed in Wisconsin into packages for consumers.)

The Paynesville plant did not make any cheese from Tuesday to Friday last week, but the new machine was ready for a test run on Saturday and started full production again on Sunday. Nearly two dozen workers were on site last week to install the new machine.

While no cheese was made last week, the plant did condense nearly 700,000 pounds of milk per day last week. Mostly the local haulers brought milk to the plant to be condensed last week.

The Paynesville plant has produced cheese since 1974, and last week's shutdown is believed to be the longest since then. Currently, over 800 farmers send their milk to the Paynesville plant.

AMPI is a dairy marketing cooperative that owns 14 manufacturing plants and markets a full line of consumer dairy products, according to a press release from the cooperative. Its 4,600 member farms annually market five billion pounds of milk.

Contact the author at editor@paynesvillepress.com • Return to News Menu

Home | Marketplace | Community